With his four-person team and in cooperation with the Graz testing-technology specialist Kristl Seibt and the Villach-based supplier of the semiconductor industry, Lam Research, Horn will spend the next seven years dealing intensively with control concepts for test bed systems in the new “Christian Doppler Laboratory for Model-Based Control of Complex Test Bed Systems”, which kicks off at TU Graz on 23rd October. “Both companies are attractive cooperation partners because they get to the bottom of the undesirable phenomena of their products in a sustainable way instead of being just being driven by specific customer requests. We find in them a number of interesting approaches for basic research in control technology,” stresses Martin Horn.

Innovation sponsored by the Federal Ministry of Science, Research and Economy

“Due to the cooperation between science and industry, the scientific basis for novel, reliable test beds will be created in the new CD lab. Not only all the partners, but also in the long run, the business and innovation location Austria will benefit from this,” says Minister of Science and Economy Harald Mahrer.Legislation for automotive test beds

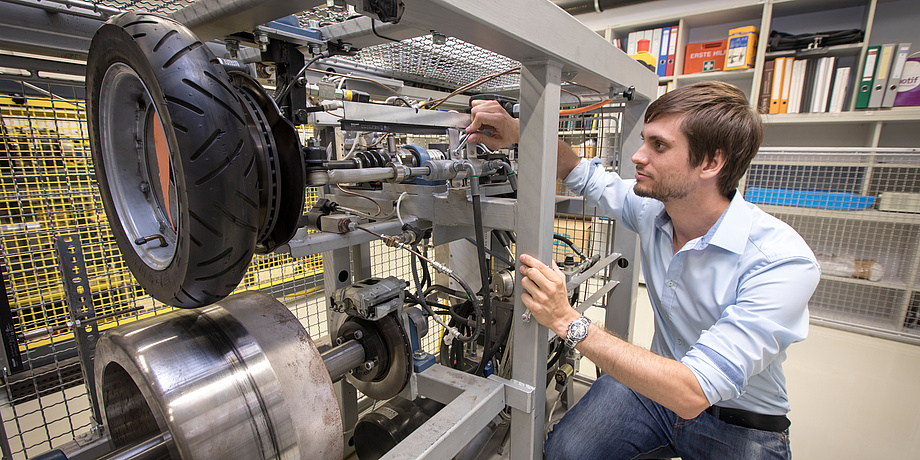

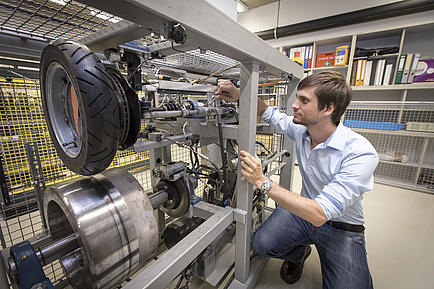

One focus of the CD lab is on the control of complex test beds for the automotive industry, for example, test beds for driving dynamics and high-voltage battery simulators, such as have been specifically developed by the Graz firm Kristl, Seibt & Co GmbH for their customers.Such complex systems always bring with them undesirable phenomena, such as vibrations or fluctuations in pressure, and in the long term require control optimisation. And to do this control technology makes use of a remarkable trick: “Not all values which you need for control can be easily measured. Both technologically and financially, it’s often not possible to attach sensors exactly where you want. So we develop virtual sensors, so-called ‘observers’, which estimate non-measurable values based on mathematical models. A special art form of control technology,” says Horn.

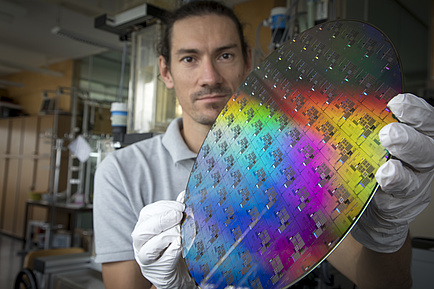

Silicon disks as a basis of semiconductor technology

The second key topic of the CD lab deals with plate-sized discs made of pure silicon crystal, so-called wafers, which go to form the basis of all semiconductor technology. Until base plates for electronic components are made from these thin disks, they go through a complex production and cleaning process which includes a large number of control technology tasks. Deviations in cleaning processes could make these disks unusable: even the smallest particles of dust destroy the structure of the wafer. For this reason, they are cleaned many many times using chemicals and temperatures in special plants. Lam Research AG, a partner of the CD lab, produces and develops such highly complex silicon-wafer cleaning plants for the semiconductor industry near Villach. “Temperature profile, wafer-rotation speeds, quantities of liquids and many other parameters of the multi-stage process have to be exactly right. And to make sure of this, apart from the previously mentioned virtual sensors, online algorithms are also necessary to determine the process parameters. While the process is taking place, possible process-critical ongoing parameters are being constantly determined using control technology methods,” says Martin Horn.Control technology in a nutshell

If problems occur in the system, potential solutions are sought by the control technology using a mathematical description of the system behaviour independent of the nature of the system. Irrespective of whether it’s a chemical, mechanical or electrical engineering application, the total complex system is broken down into the smallest model possible. This allows the control technicians to identify any optimisation possibilities of the system behaviour. “Altering the course of the engine speed in a plant or a particular air-humidity value in the chamber can lead to the desired improvement of the whole system. Exactly which screws and levers have to be turned to achieve the desired behaviour of the whole system can be discovered by using appropriate control technology methods,” explains Martin Horn. Aktive (and already opened) CD labs at TU Graz:- CD-Laboratory for Model-Based Control of Complex Test Bed Systems

- CD-Laboratory Brushless drives for pump and fan applications

- CD-Laboratory for Fiber Swelling and Paper Performance

- CD-Laboratory for Semantic 3D Computer Vision

- CD-Laboratory for Lithium Batteries - Ageing Effects, Technology and new Materials