News+Stories: PV soiling – could you briefly explain exactly what this is?

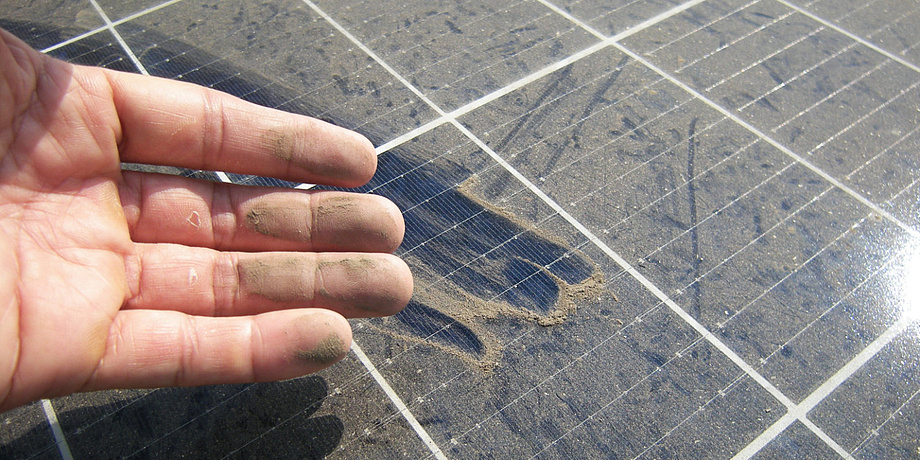

Armin Buchroithner: PV soiling is the soiling of photovoltaic modules that leads to a significant reduction in their yield. Over the last 50 years, a great deal of effort has gone into increasing the efficiency of photovoltaic cells from 16 to 22 per cent. Undoubtedly a great achievement – but one that counts for nothing if the systems get dirty. The sources of PV soiling are many and varied. Pollen, sand, dust and soot, but also abrasion from tyres and brakes when PV modules are mounted on noise barriers, for example, are responsible for relatively homogeneous soiling. What might not occur to you at first is bird droppings or wet leaves. In terms of surface area, the contamination may not be large, but in PV modules the cells are connected in series. Shading by e.g. ten per cent of the area due to dirt can reduce the yield by 50, 60, sometimes even 80 per cent.

How is such soiling usually removed?

Armin Buchroithner: The range is huge: from robotic cleaning on some large plants, to heavy goods vehicles with brushes, water and high-pressure cleaners, and cleaning staff on foot who clean the modules by hand or with high-pressure cleaners. Incidentally, the water must be distilled to prevent (limescale) deposits. The most common method is manual cleaning, i.e. someone runs through the system with high-pressure cleaners, cloths or brushes. In the case of solar cells integrated into buildings or on slanted roofs, this is of course often impractical, which means that soiling can permanently reduce the output of the systems.

A secondary effect of soiling is abrasion, i.e. scratching of the surfaces, which causes the glass on the front of the module to become milky. This particularly affects regions with high wind speeds and high levels of dust – deserts, for example. Cleaning is definitely an important factor there, and also incurs relevant costs.

How does a system operator know when it is the right time to clean the modules?

Armin Buchroithner: A visual inspection is of course an obvious option, but not always practical or reliable. Particles that are deposited on PV modules sometimes have very different properties – often indistinguishable to the naked eye. An automated detection system would require the appropriate measurement technology. You would have to measure the solar radiation precisely with a pyrheliometer and combine the value with the temperature in the PV module in order to determine the expected output of a PV system. If there is a large discrepancy between the potential and the actual performance, cleaning is required.

Precise signal evaluation is a decisive factor here. This is because you cannot simply take the total output of a system and divide it by the area of the modules. You would have to analyse exactly which module supplies how much energy. This requires the construction and distribution of small measuring stations in order to analyse the situation at a higher spatial resolution.

After the question “When should they be cleaned?” comes the question “how?”

Armin Buchroithner: An automated cleaning system would certainly be desirable, but would it be economically viable? If I measured exactly how high the losses due to soiling are and included the electricity prices in the calculation, I could compare this with an automated cleaning system. But fully automated cleaning systems are still the subject of research – there are approaches in the direction of spray nozzles, and wiper blades are also a possible variant.

Why hasn’t an automated cleaning system been able to establish itself yet?

Armin Buchroithner: The additional costs are a key point. The challenge is that you have to bring moving components into a static system, which causes additional costs. But there are signs of a paradigm shift, at least for newly planned large-scale plants. If the fluctuating electricity price is included in the calculation, single-axis tracking of the modules can now be cheaper than the classic static set-up. If I track the modules from east to west during the course of the day, I have 20 to 30 per cent more yield, depending on the location, especially in the morning and afternoon. If I track on two axes, i.e. also adjust the alignment to the height of the sun, the module surfaces are always aligned orthogonally to the solar radiation. This increases the annual yield by up to 40 per cent, depending on the location.

What does this have to do with cleaning?

Armin Buchroithner: These rotational movements of the modules could be exploited by connecting them to a static cleaning device, e.g. a wiper blade or a brush strip along which the module travels. The advantage is that the system does not move for the relatively infrequent cleaning required, but every day to increase the yield. Cleaning is therefore carried out in passing and is thus cost-effective.

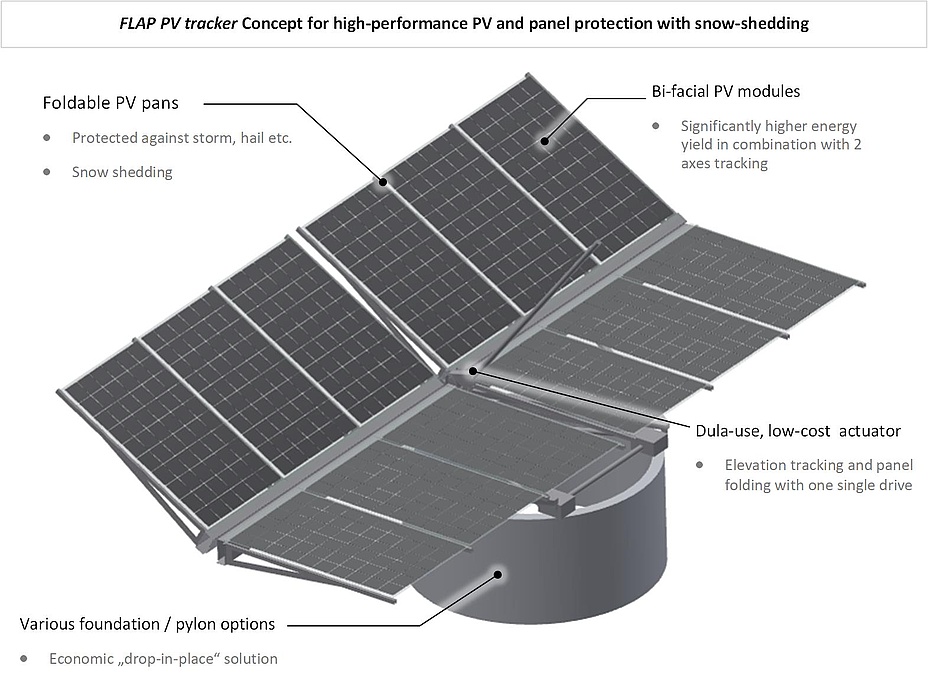

We have applied for and received a European patent for such a dual-use actuator, which could potentially be combined with a static cleaning device. The “FLAP PV” is a two-axis tracker, but with only one actuator. Two solar modules follow the path of the sun, but can also be folded face-to-face and placed close to the ground [a video of FLAP PV]. This is done at night, among other things, which greatly reduces the time during which soiling can occur. Or in the event of snow or hail. After all, hail damage is a problem for PV systems, and it doesn’t even have to break the front glass. By compressing the silicon wafer, hail can also cause so-called hotspots, which have an increased internal resistance and thus heat up locally, which reduces the efficiency of the module. If the modules are folded up before hail showers, the exposed surface is halved and the front completely protected. The rear sides of bifacial modules, whose undersides capture and utilise the scattered sunlight, could be covered with a cheap hail net. This would be irrelevant for the diffuse radiation in terms of efficiency.

And how could this mechanism be combined with an automatic cleaner?

Armin Buchroithner: In systems such as our FLAP PV, a static wiper blade could be installed – similar to a ribbon in a bound book – which runs along the inside of the modules when they are folded. The additional costs for such a wiper or brush strip would be relatively low compared to an active cleaning device with its own actuators.

In fact, the folding mechanism also has other positive effects. In winter, it protects against shading from snow, and the folded modules offer significantly less surface area in the event of a storm, which prevents damage. Our next goal is to prove the robustness of our FLAP PV system in practice. In my opinion, this would be a great demonstration project for Innovation District Inffeld.