Small electrical gadgets, such as mobile phones, tablets or notebooks, are indispensable accompaniments of everyday life. Integrated circuits in the interiors of these devices monitor, control and regulate the most varied processes. A ubiquitous trend in microelectronics is towards the smaller, more mobile and more diverse. And this shows how important the research results published in Scientific Reports by the research team led by Michael Sternad and Martin Wilkening from the Christian Doppler Laboratory for Lithium Batteries at TU Graz’s Institute for Chemistry and Technology of Materials are. The on-board power supply of a microchip could definitely extend the range of applications of microelectronics.

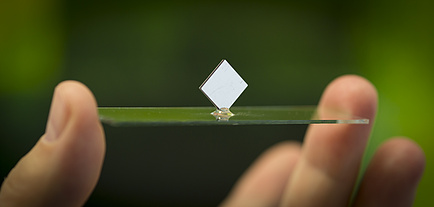

Electrochemists at TU Graz have managed to use monocrystalline semiconductor silicon as an active storage electrode in lithium batteries. This enables an integrated power supply to be made for microchips with a rechargeable battery.

Small electrical gadgets, such as mobile phones, tablets or notebooks, are indispensable accompaniments of everyday life. Integrated circuits in the interiors of these devices monitor, control and regulate the most varied processes. A ubiquitous trend in microelectronics is towards the smaller, more mobile and more diverse. And this shows how important the research results published in Scientific Reports by the research team led by Michael Sternad and Martin Wilkening from the Christian Doppler Laboratory for Lithium Batteries at TU Graz’s Institute for Chemistry and Technology of Materials are. The on-board power supply of a microchip could definitely extend the range of applications of microelectronics.

Information

Link to the publication:

M. Sternad, M. Forster, M. Wilkening, The microstructure matters: breaking down the barriers with single crystalline silicon as negative electrode in Li-ion batteries, Sci. Rep. 6 (2016) 31712. DOI: 10.1038/srep31712

Link to CD Laboratory for Lithium Batteries - ageing effects, technology and new materials

Website of the Christian Doppler Research Association

Contact

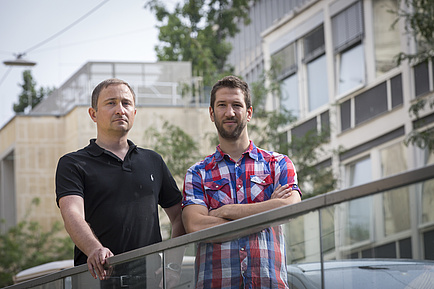

Dipl.-Ing. Dr.techn.

Institute for Chemistry and Technology of Materials

CD Laboratory for Lithium Batteries

Mobile: +43 664 463 2727 | Tel.: +43 316 873 32320

michael@sternad.com

Martin WILKENING

Univ.-Prof. Dr.rer.nat.

Institute for Chemistry and Technology of Materials

CD Laboratory for Lithium Batteries

Mobile: +43 664 88796957 | Tel.: +43 316 873 32330

wilkening@tugraz.at

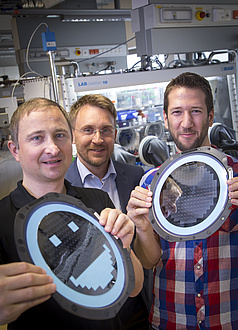

![[Translate to Englisch:] © Lunghammer - TU Graz At the Christian Doppler Laboratory for Lithium Batteries at TU Graz Michael Sternad, Martin Wilkening und Georg Hirtler (from left to right) managed to use monocrystalline silicon, which microchips consist of, directly as a battery electrode. Thus the mi](https://www.tugraz.at/fileadmin/_processed_/5/8/csm_wilkening_005_by_lunghammer-TU_Graz_01d95809ff.jpg)