News+Stories: You studied mechanical engineering at Graz University of Technology (TU Graz). Why did you choose this degree programme?

Julian Torggler: My father is an engineer and has been a teacher at a vocational school for a long time, and somehow I must’ve caught the bug at home. I was interested in vehicles and mobility in general from a very early age. I always wanted to know exactly how something works or why it works the way it does. I studied at a HTL (higher technical college) – in South Tyrol it’s called a “university of applied sciences” – and studied mechanical engineering, so it was a relatively clear path for me from an early age.

As a South Tyrolean, why did you come to Austria, to TU Graz, to study?

Julian Torggler: We looked at several universities, mainly in German-speaking countries, and were also in Munich and Vienna. Graz was the most appealing to us overall – in terms of the university itself and the orientation of the education. By “us” I mean seven students from our HTL class at the time who all came to Graz. We then supported each other at the beginning of our studies.

That means all seven of you started at TU Graz?

Julian Torggler: No, three went to the Joanneum University of Applied Sciences and the remaining four chose mechanical engineering or mechanical engineering and business economics at TU Graz.

How did you find out about the mechanical engineering study programme beforehand?

Julian Torggler: We happened to be in Austria from the HTL in our final year and looked at various companies here. We were in Steyr and visited the BMW Group plant in Steyr, we were in Bruck at Pankl Racing Systems and then in Graz we visited AVL and by chance we had our first contact with TU Graz there. Then we went to Graz in the summer and talked with the student representatives for mechanical engineering who gave us extensive information, which was very useful.

On the Bachelor’s Degree Programmes web page you will find a list of Bachelor’s degree programmes at TU Graz from A to Z, each with details about the individual programmes, admission, outlook for the future after the Bachelor’s degree and more. The Advisory Services for Prospective Students website offers an overview of all advisory services, such as the annual Open Day during the week after Easter, a link to the student representatives of the University Students’ Union at TU Graz (HTU Graz) or information about registration and admission.

What were your expectations before you started studying? What was very different then?

Julian Torggler: What surprised me was the first step in organising my life as a student. What I mean is that you have to register for courses yourself, find the lecture halls yourself, and that you really have to behave independently as a student. In the beginning, there was a lot of information in such a short time and we found the basic subjects relatively demanding, but you get used to it quickly. It was much faster than at school. You get to know other fellow students quickly and realise that studying involves working as a team.

You wrote your Master’s thesis on railway engineering. Have you always been fascinated by trains?

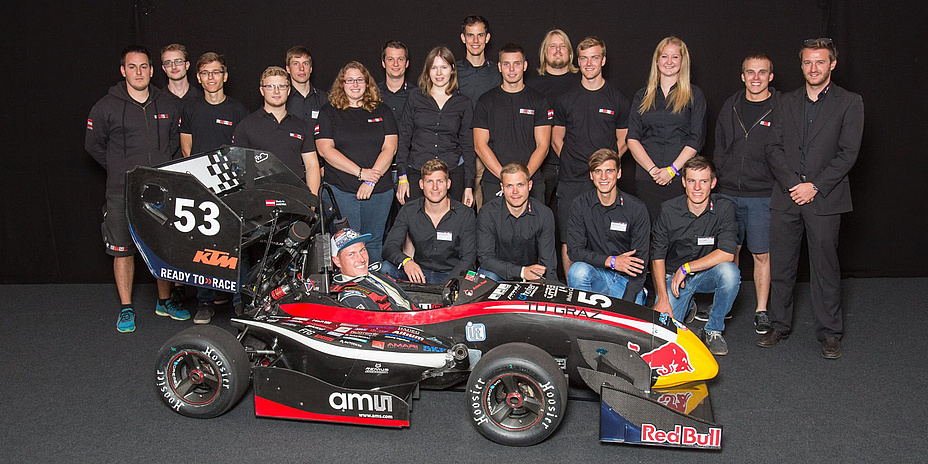

Julian Torggler: I used to travel many hours home by train in my student days, but to be honest I didn’t think too much about the technical side of it at the time. Actually, I was more interested in cars, and was intensively involved in the TU Graz Racing Team for three years during my Bachelor’s degree and specialised in vehicle technology and safety during my Master’s degree.

There are six specialisations in the Master’s programme in Mechanical Engineering at TU Graz: Production technology, energy technology, computational engineering, product development of mechatronic systems, engine and drive technology, vehicle technology and safety. The TU Graz web page of the Master’s programme in Mechanical Engineering provides comprehensive information about the study programme.

Three years in Formula Student? That sounds exciting.

Julian Torggler: Yes, that was a very intensive time (laughs). I joined during my Bachelor’s degree studies through a colleague from South Tyrol and became thoroughly involved. For one year I was also head of the “chassis” division and had a team that I worked with. That opened up a lot of new perspectives for me.

What perspectives in particular?

Julian Torggler: I learned how to get in touch with companies. For students, there are of course the career fairs, such as Teconomy Graz, where companies are represented, but with the TU Graz Racing Team we had to actively contact sponsors in order to be able to design and build the best Formula Student racing car. We were at Silverstone in England at the race track and got to know international racing teams live. We then had a great opportunity to go to Japan for just under one and a half months, where we competed. And we were also in America, so we really travelled the world, which was completely new territory for me and really exciting. Getting to know so many people from other regions has broadened my horizons in the sense that I became aware that there are different approaches elsewhere than here.

Did being part of the student team demand a lot of time?

Julian Torggler: Your studies are pretty much on hold for a year. I made use of the two tolerance semesters in the TU Graz Racing Team. For me, it was very enriching to get practical experience that you can’t gain from your studies. In the TU Graz Racing Team, the team members actually build the vehicle themselves. For me, it was worth the time.

At TU Graz, there are a large number of student teams in which students can develop their practical skills and social competences, establish contacts with business, industry and research and, of course, make friends. More information is available on the Overview: Student Teams web page.

So how did your interest then shift from automotive to railway technology?

Julian Torggler: A colleague from the student team had started his Master’s thesis in railway technology before me. We were together in the TU Graz Racing Team workshop at Campus Inffeldgasse, and because the Institute of Structural Durability and Railway Technology is right next door, we just stumbled into it at some point (laughs). And railway technology suited me right from the start.

What was it about railway technology that suited you so well?

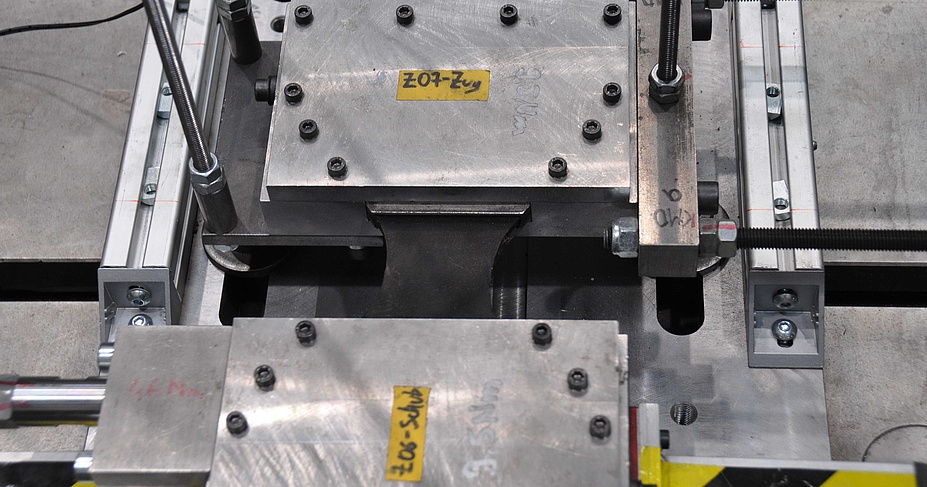

Julian Torggler: I discovered for myself that railway technology can be very challenging and exciting. At the Institute of Structural Durability and Railway Technology at TU Graz there is a large and relatively unique testing hall with very imposing components, a lot of “classical” mechanical engineering, so to speak – a lot of steel structures and a lot of fatigue tests. In the automotive industry, it’s more about optimisation, you work very much in detail and its very cost-driven. At the Institute we are really still conducting research into the basics, it is possible to work on something new and not just develop the existing situation. I was very enthusiastic about that.

And above all, the plans are longer term. Because of the larger timeline, you can conceive of everything further and on a bigger scale. I don’t have to develop a completely new vehicle in one year and then launch it on the market; instead, these projects have five to ten-year horizons.

At the Institute of Structural Durability and Railway Technology we are really still conducting research into the basics, it is possible to work on something new and not just develop the existing situation. I was very enthusiastic about that.

With your Master’s thesis, you won first prize in the Siemens Railway Engineering Award from Siemens Mobility. How did that come about?

Julian Torggler: The Institute has had a close cooperation with Siemens Mobility Austria in Graz for a very long time – the so-called “Siemens Class” is part of this. As a student, I became part of this Research Innovation Ecosystem (RIE) with my Master’s thesis, whose aims were set by Siemens Mobility Austria, and I am now also working in this framework on my doctoral thesis.

For his Master’s thesis, Julian Torggler received the 1st prize of the Siemens Railway Engineering Award of Siemens Mobility Austria in Graz. With the Austria-wide award, Siemens Mobility Austria rewards outstanding achievements in the field of public transport that focus on the topic of rail. The prize is awarded in cooperation with universities of technology and universities of applied sciences in Austria.

What were the advantages of writing your Master’s thesis for Siemens Mobility Austria as part of the RIE cooperation?

Julian Torggler: The dialogue with the contact persons and colleagues at Siemens, which I still have now in a joint monthly regular meeting, was very helpful from a professional point of view. There were many interesting inputs from an industry perspective. And there is support when we need materials for research or contacts to suppliers. In the research project, we test components that come from the suppliers. As a university institute alone, it would be difficult to get the components we need. That’s a great addition here.

Due to the Research and Innovation Ecosystems (RIE) programme, TU Graz’s strategic partnership with Siemens in the field of railway technology has been expanding since 2021. The RIE lives in the so-called “Siemens Class”, consisting of all students involved in joint research projects. On the web page Partnerships with Business and Industry, you will find more information about the RIE and other partnerships of TU Graz, for example with Magna Steyr Fahrzeugtechnik, AVL List, the Science Park Graz and many more. Under Corporate Partners of TU Graz you can find information about the business partners of TU Graz.

That means your Master’s and doctoral theses are about rolling stock?

Julian Torggler: Correct. The Master’s thesis was about taking a sample from a component and characterising the material, i.e. testing how the material behaves in different combinations. Because there are no really standardised samples for such materials used in the suspension between the railway carriage and the undercarriage, we developed our own. My task in the Master’s thesis was to test these samples on the test field and verify the developed geometry. The doctoral thesis investigates the fatigue strength of the material. I examine under which conditions in operation it withstands the stresses and for how long. Siemens’ wish was to be able to estimate more precisely in advance how to dimension certain components correctly.

What role does that play?

Julian Torggler: For instance, for sustainability. The aim is to use the material as efficiently as possible and, if necessary, to use better combinations of materials. Of course, we could make the component much more massive or stronger, that’s how it works in operation anyway. The approach today, however, is to better understand when and why the material breaks down, how long it will hold up, so that you can keep it in service and operating safely for as long as possible and not consume unnecessary material resources.

You are a project assistant at the Institute of Structural Durability and Railway Technology at TU Graz. What does that entail?

Julian Torggler: Yes, I’m a project assistant here at the Institute. My task is research in the “Fatigue behaviour of cord rubber composite materials” cooperation project between TU Graz and Siemens. Unlike university assistants, I don’t have any teaching duties – but I am happy to provide support if needed.

Research is currently a great playground for me (laughs). We can try out a lot of things, we can decide and implement a lot on our own. I find that very exciting.

After you finish your doctoral thesis, will you go into industry or research?

Julian Torggler: I’m not quite sure yet, but I think there is a good possibility through the contact with Siemens that I can continue working there in my present direction. Or an opportunity for further research will arise at the Institute. I’m about halfway through my doctoral thesis and don’t want to rule anything out yet. Research is currently a great playground for me (laughs). We can try out a lot of things, we can decide and implement a lot on our own – of course always in consultation with our colleagues and project partners. I find that very exciting. There is no predefined way to make it work. This can sometimes also be a disadvantage when things don’t work out as expected. But dead ends are also part of everyday life in research.