Photographic material available for download at the end of the text.

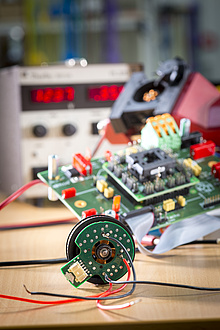

Energy demands are constantly rising worldwide. At the same time there are increasingly strict environmental constraints – especially for industry. The salient point is to make use of electrical energy as efficiently as possible, and not only in the larger main drives. “Even a vehicle’s auxiliary drives require large amounts of energy – for instance fans for the radiator, hydraulic pumps for the power steering, and power seats and windows. This is also true for household appliances and a variety of other auxiliary power units in other applications. What are specially suitable here are so-called integrated brushless drives, and we want to optimize various aspects of them in the framework of the new CD Lab along with Mechatronics Systems GmbH,” says Annette Mütze of TU Graz’s Institute for Electrical Drive Propulsion and Machinery. She heads the “Christian Doppler Laboratory for Brushless drives for pump and fan applications”, which was opened today on 26 September at TU Graz.

Even a vehicle’s auxiliary drives require large amounts of energy – for instance fans for the radiator, hydraulic pumps for the power steering, and power seats and windows.

Innovation sponsored by the Federal Ministry of Science, Research and Economy

“Efficient auxiliary drives for energy-efficient cars – this is a challenge that has to be faced by domestic automotive suppliers,” says Dr. Reinhold Mitterlehner, Minister of Science, Research and Economy and Vice-Chancellor. “New knowledge from the CD Lab leads to new solutions and enhances the innovative power and competitiveness of the corporate partner. This benefits Austria as a science and business hub, and especially the southern Styrian region, by creating new and high-value jobs.”

Improving efficiency

Many systems using electric drives are undergoing continued technological development and will replace older systems – provided that the same level of comfort can be offered at acceptable prices. Annette Mütze continues: “Hydraulic components or pumps and fans which are controlled by reducing the power flow are being increasingly replaced by electric systems. This presupposes, however, that sufficient electrical energy is available in the system and can be used efficiently. Hence we have to considerably improve the efficiency of these components. Weight, capacity and material consumption are important levers. Specifically, as a first step, the CD Lab team will create analytic models for brushless drives with a significantly raised degree of efficiency and optimized speed and torque density. After this, scaling rules will be worked out and cost factors taken into account so that the corporate partner can translate the basic knowledge obtained in the CD Lab into real production.

Specialised SME as partner

Mechatronics Systems GmbH, with head office in Wies in southern Styria, is an SME and is part of the new CD Lab. Established in 2005, the company develops and produces mechatronic components and systems.

This Christian Doppler Laboratory ist attributed to the Field of Expertise "Mobility & Production“, one of TU Graz' five strategic areas of research.

![[Translate to Englisch:] © Lunghammer - TU Graz](https://www.tugraz.at/fileadmin/_processed_/2/3/csm_Banner_CDLabor_Elektrische_Antriebe_by_Lunghammer_tugraz_cf14a8b064.jpg)