Hydrogen embrittlement is a major concern for the automotive, construction, and energy sectors. It limits the use of new ultra-high-strength steels, which have huge advantages in reducing raw material consumption, decreasing fuel consumption, and decreasing carbon dioxide emissions. The Institute of Materials Science, Joining and Forming has carried out intensive studies underpinning the harmful effects of hydrogen on steels and to defeat hydrogen’s detrimental effects.

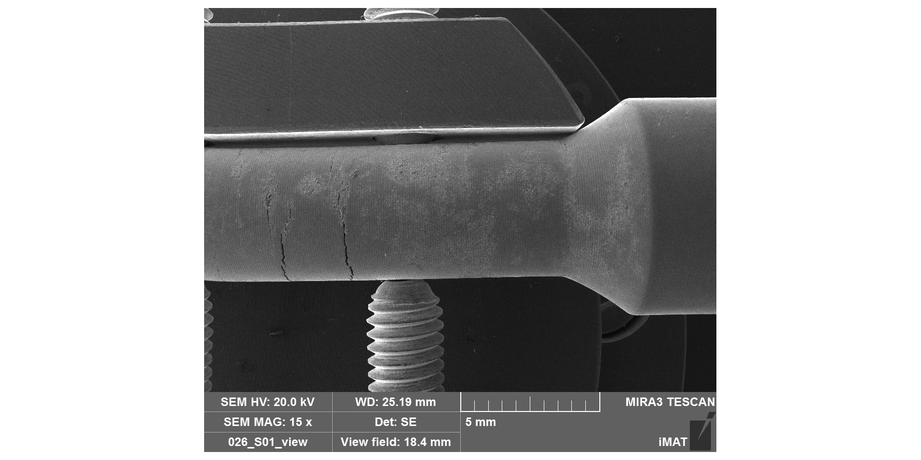

The global trend in modern lightweight steel construction in the automotive industry increases the need for ultra-high-strength steels (UHSS) with an ultimate tensile strength above 1,500 MPa. Due to the downsizing of steel structures, CO2 emissions are significantly reduced. However, UHSS are susceptible to HE, which restricts the use of the materials and makes component assessment difficult. Hydrogen can be taken up during steel production, thermal and mechanical processing, coating, or service. Smallest amounts of hydrogen in the microstructure can lead to time-delayed and thus unexpected brittle failure of UHSS screws. The delay in time is particularly crucial because it is difficult to predict the time of critical hydrogen uptake and thus to prevent brittle failure.

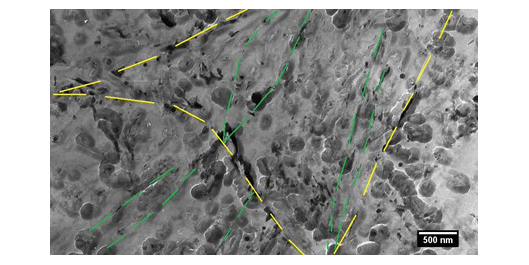

Figure 2: TEM analysis, showing high-resolution microstructural constituents and intensive precipitation [Dománková, 2019].

In the past two years, the Institute of Materials Science, Joining and Forming at TU Graz has established an intensive research project in cooperation with voestalpine Wire Rod Austria GmbH in St. Peter-Freienstein, one of Europe’s leading manufacturers of wire rod, and the Centre of Excellence for Electrochemistry and Surface Technology (CEST) in Wiener Neustadt and Linz, which is one of the Austrian COMET centers for applied research. The project combines fundamental and applied research to undermine the harmful effect of hydrogen on different microstructural constituents, to design new materials, and to optimize the heat treatment process.

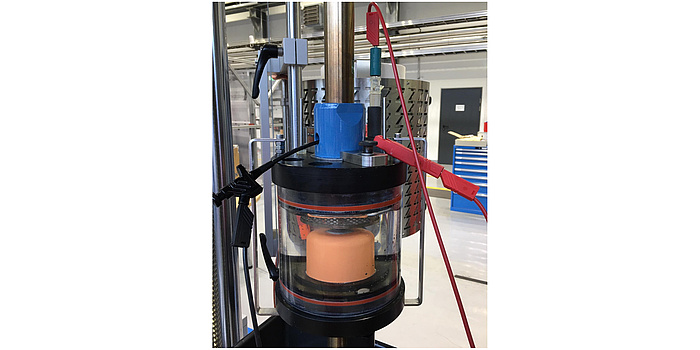

Figure 3: In-situ HE testing cell during mechanical loading.

The key development activities in the research project are

- the experimental techniques for the microstructural sensitive evaluation of HE resistivity and

- the validation of integrated multiscale material models.

Advanced Microstructural Characterization

With proper alloy chemistry and heat treatment, it is possible to reduce HE susceptibility and increase steel strength.

To this end, changes are made to the microstructure concerning the following mechanisms:

- beneficial hydrogen trapping by nano-precipitates

- grain refinement and

- reduction of internal micro-stresses.

New alloy concepts can be investigated with a new smelting device available at voestalpine for very small melt batches of 45kg. To apply different heat treatments, ovens with oil and salt baths are used. The investigation of the microstructure was applied using many techniques such as LOM, SEM, TEM, XRD, and EBSD, to determine the phases, grain size, sub-grain size, dislocation density, precipitates (size, shape, and chemical composition).

In addition, thermal desorption spectroscopy (TDS) was performed to investigate the hydrogen distribution in the microstructure. It was found that hydrogen segregates at the precipitate-matrix interfaces and the dislocations.

To optimize the industrial heat treatment process concerning the total precipitate-matrix interface area, a MatCalc routine was developed. MatCalc is a thermodynamic software which includes physical principles and is thus capable of handling complex alloy systems and complex heat treatments. For calibration, the necessary parameters are obtained from TEM and TDS analysis.

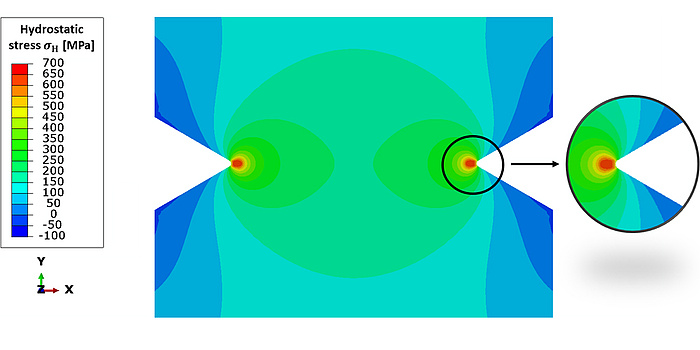

Figure 4: Development of a digital twin of the in-situ HE testing cell. 1: Mechanical simulation of the hydrostatic stress field at a screw notch. 2: Diffusion simulation of the hydrogen accumulation in the strained area during mechanical loading.

Hydrogen embrittlement (HE) testing and simulation

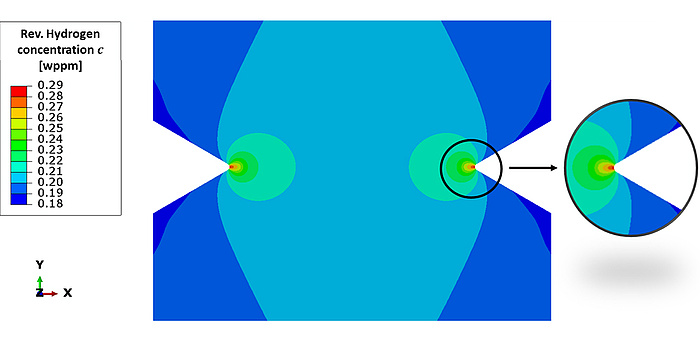

To understand the effects of hydrogen accumulation at a notch, a new in-situ HE testing cell was designed and established to evaluate the resistivity to HE and stress corrosion cracking. The special feature of this cell is that it allows the precise control of the hydrogen uptake by cathodic polarization or under corrosive conditions.

A new 250kN electro-mechanical machine currently performs slow strain rate tests (SSRT) and incremental step load tests (ISLT). In addition, a multiphysical finite element model (FEM) of the in-situ testing device was developed and parametrized. This model allows the hydrogen accumulation at the notch during SSRT to be simulated as a function strain rate. It was found that the strained area at the notch can increase local hydrogen concentration up to five times compared to the measured average bulk concentration.

In an initial study, the beneficial role of nano-precipitates, which is still under debate in the literature, was evaluated. For this purpose, two different steel alloys were produced: one precipitation rich (containing Cr-Mo and V) and one precipitation free (containing Si and Mn) steel. The former alloy can trap hydrogen and the latter can dissolve it in the microstructure. The investigations always focus on the goal to prevent a movement of atomic hydrogen, especially from corrosion reaction during loading, which can happen in service within the steel microstructure.

In a second study, the Quenching and Partitioning (Q&P) heat treatment was intensively studied. It is a promising approach for producing a microstructure of martensite (M) and carbon-enriched retained austenite (RA). This complex microstructure imparts high strength to the steel due to the presence of M and high ductility due to the presence of a considerable amount of RA. Because of the high solubility of hydrogen in RA, which acts as a strong trap, the resistance against HE should be increased, but this is not the case. There is a contradiction between results from different investigations in this area. The crucial factor, however, is the RA stability and shape. When the RA is stable and in thin layers around the tempered M, it acts as a barrier and binds the hydrogen, thus preventing it from reaching sensitive phases; in turn, the HE susceptibility should decrease.

Outlook

The simultaneous use of microstructural sensitive testing procedures and integrated physically based material models make a contribution to our project by reducing the HE of the high strength screws and fasteners applied in lightweight mobility and the planned CO2-free energy production. Our understanding of different microstructural constituents regarding the hydrogen distribution and HE contributes sustainably to making a safe use of UHSS possible – and has in this way still a huge development potential.

This research area is anchored in the Field of Expertise “Advanced Materials Science”, one of five strategic foci of TU Graz.

You can find more research news on Planet research. Monthly updates from the world of science at Graz University of Technology are available via the research newsletter TU Graz research monthly.