More pictures available at the end of the text

The ministry for infrastructure is setting up its own pilot factory for Industry 4.0 in Styria. Domestic firms will be able to try out digitalised production technologies in the test lab in Graz without disturbing their own operation. Research will be carried out on new production methods at the “smartfactory@tugraz” through which small quantities will be able to be viably produced, such as custom-made cars. Special attention will be paid to data security and reliability of computer-controlled production systems. Graz University of Technology will have overall responsibility and will participate in the project together with about 20 domestic companies. The ministry for infrastructure is investing two million euros in the Graz location, and about the same amount will be contributed from partners from business and science.

“In the pilot factory, our domestic companies can try out today the digital production of tomorrow. In the future, small and medium-sized enterprises in Graz will develop new methods to create unique pieces on the assembly line. And in such a way that they will be affordable for the customer. In the future, we won’t choose between different car models, but rather the vehicle will be put together based on our own wishes – from design to engine to interior trim. The pilot factory will help us to prepare our companies for digitalisation. And in this way we’ll bring more jobs to Styria,” says infrastructure minister Jörg Leichtfried.

“In the form of the smartfactory@tugraz, TU Graz will gain an ideal research environment to carry out research on agile and secure production concepts of the future and Styria an interdisciplinary and business-friendly pilot factory. Scientists across many disciplines – mechanical engineering, electrical engineering and computer science, for instance, – will teach and carry out research at an inter-faculty level. The smartfactory@tugraz is the perfect complement to the smart production research focus of TU Graz and is turning Styria into one of the leading European smart production and services regions and making our enterprises fit for the challenges of the future,” says a delighted Harald Kainz, Rector of TU Graz, referring to the new facility.

“Advancing digitalisation is the answer to increasing international competition. By means of new digital methods we can achieve increases in efficiency in production and develop new services and innovative business models and thus keep jobs and value-added in Austria. For this reason we’re participating very actively in the pilot factory. Together with young people, we want to do research on future intelligent forms of production and develop research fields for industry,” says Kurt Hofstädter, head of the Digital Factory division at Siemens Österreich, and welcoming the establishment of the pilot factory.

Apart from the existing pilot factory at Vienna’s Urban Lakeside Aspern and smartfactory@tugraz, Linz is also getting a pilot factory, in which research will be carried out on new processing techniques. These “demo factories” are lifelike factory models and will help to make new developments ready for the market faster. The reason this is so important is that production is currently going through a far reaching transformation. People, products, machinery and materials communicate with each other in increasingly complex computer-controlled systems and by internet. A prominent catch word for this development is Industry 4.0 – the fourth industrial revolution after mechanisation, electrification and automation. The ministry of infrastructure funds research and development in the field of Industry 4.0 to the amount of 185 million euros per year. Apart from the pilot factories, endowed professorships, continuing education in companies, such as the “Fit 4 4” programme, and studies of the effects of Industry 4.0 on training and the labour market in Austria are being funded.

An initiative of the Field of Expertise „Mobility and Production“ at TU Graz

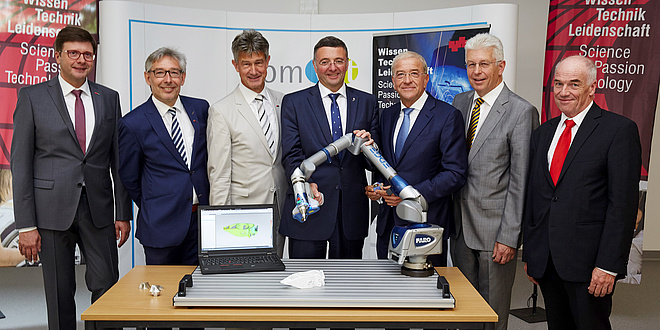

![[Translate to Englisch:] © Peter Melbinger - TU Graz](https://www.tugraz.at/fileadmin/_processed_/c/c/csm_smartfactory009_by_Foto_Peter_Melbinger_by_TU_Graz1_8e60e4b058.jpg)