They power aeroplanes, cargo and cruise ships, construction machinery and power stations. But they also have a reputation for damaging the environment and contributing to the climate crisis. Nevertheless, large engines are currently an integral part of our lives. This is why there are intensive research endeavours to convert these (still) necessary engines to environmentally friendly fuels, to reduce their consumption or to completely rethink them.

The TU Graz dossiers take a comprehensive look at a research question and show the different approaches that researchers at TU Graz are taking to address it.

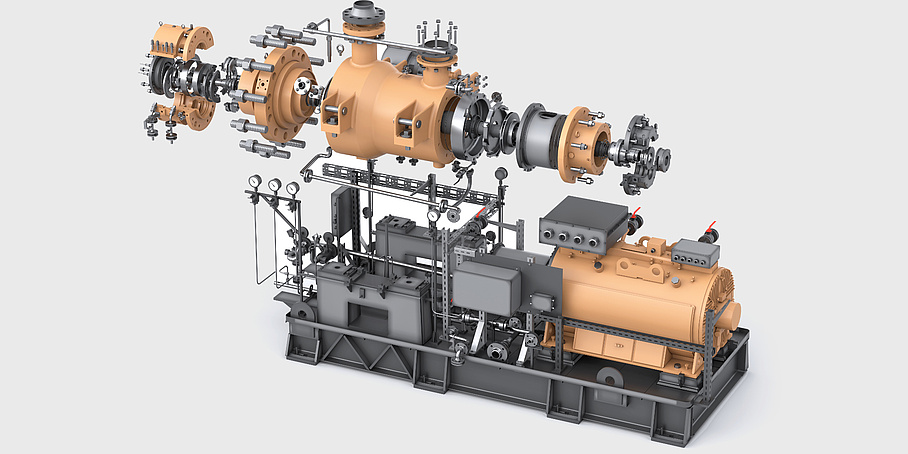

Only One Megawatt is Powerful Enough

They are standard on trains, but on container ships still a dream of the future: Large electric motors are constantly evolving and are used for numerous applications. What are their advantages and disadvantages?

New fuels for climate-neutral marine transportation

Methanol, ammonia, and hydrogen are waiting in the wings to replace problematic heavy fuel oil in ship propulsion systems. In this interview Nicole Wermuth and Andreas Wimmer explain the differences between the three variants, and look at the design requirements for the engines that will burn them.

Dynamic giants

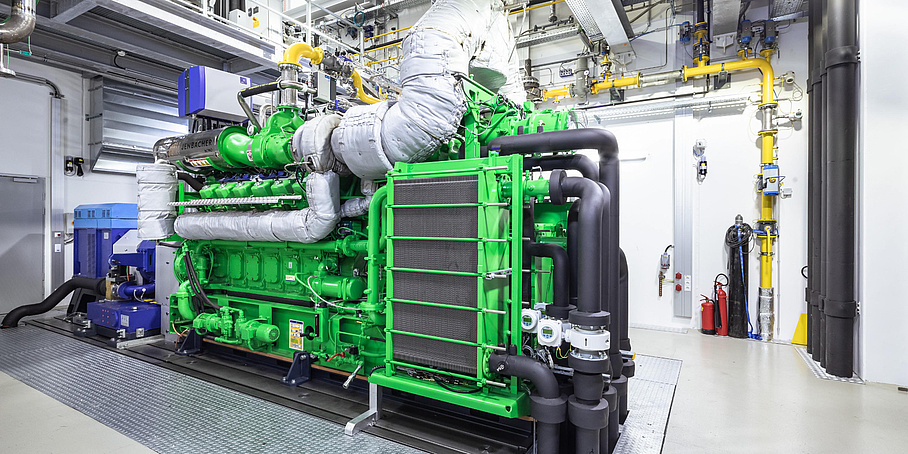

For a long time, large engines only knew one operating condition: full load. Nowadays, though, they are used much more flexibly and can effectively balance fluctuating electricity production, in particular from renewable energy sources.

Will environmentally friendly aviation soon be a reality?

Robert Krewinkel has been Head of TU Graz’s Institute of Thermal Turbomachinery and Machine Dynamics since October 2023. He explains the latest breakthroughs in aircraft engines and which direction the technology is heading in.

New Professorship for Large Engines Research at Graz University of Technology

As Professor for "High-performance Large Engine Systems", Nicole Wermuth is researching sustainable fuels, emission reduction and higher efficiencies for the green transformation of large engines.

In the Turbo-machinery Laboratory at TU Graz

In the Turbomachinery Laboratory at the Institute of Thermal Turbomachinery and Machine Dynamics at TU Graz, Emil Göttlich, head of the laboratory, and his research team study the aerodynamics of aircraft engines.

From the Archiv: Andreas Wimmer: "Import of Green Energies Necessary"

Andreas Wimmer conducts research on large engines at TU Graz and heads the LEC research center. Hydrogen, methanol and ammonia will play a central role in achieving climate targets.