Paper down to fibre level

Paper is everywhere and has to satisfy all manner of requirements. For a start, it has to be permeable to air, stable and tear-resistant. It must also optimally absorb pigments and avoid undesirable changes of shape if it is wetted. Depending on the application, these properties must be combined perfectly. The new “CD Laboratory for Fibre Swelling and Paper Performance” at Graz University of Technology will investigate how to optimally combine the key characteristics of paper to achieve the desired result.

The Federal Ministry of Science, Research and Economy of Austria sponsors innovation

“Wood and paper are industries with a long tradition in Austria,” explains Dr. Reinhold Mitterlehner, Austria’s Federal Minister of Science, Research and Economy. “The laboratory will contribute to technological progress in these important segments. This will benefit all participating partners and, in the long term, Austria as a location of industry.”

Optimal fibre swelling

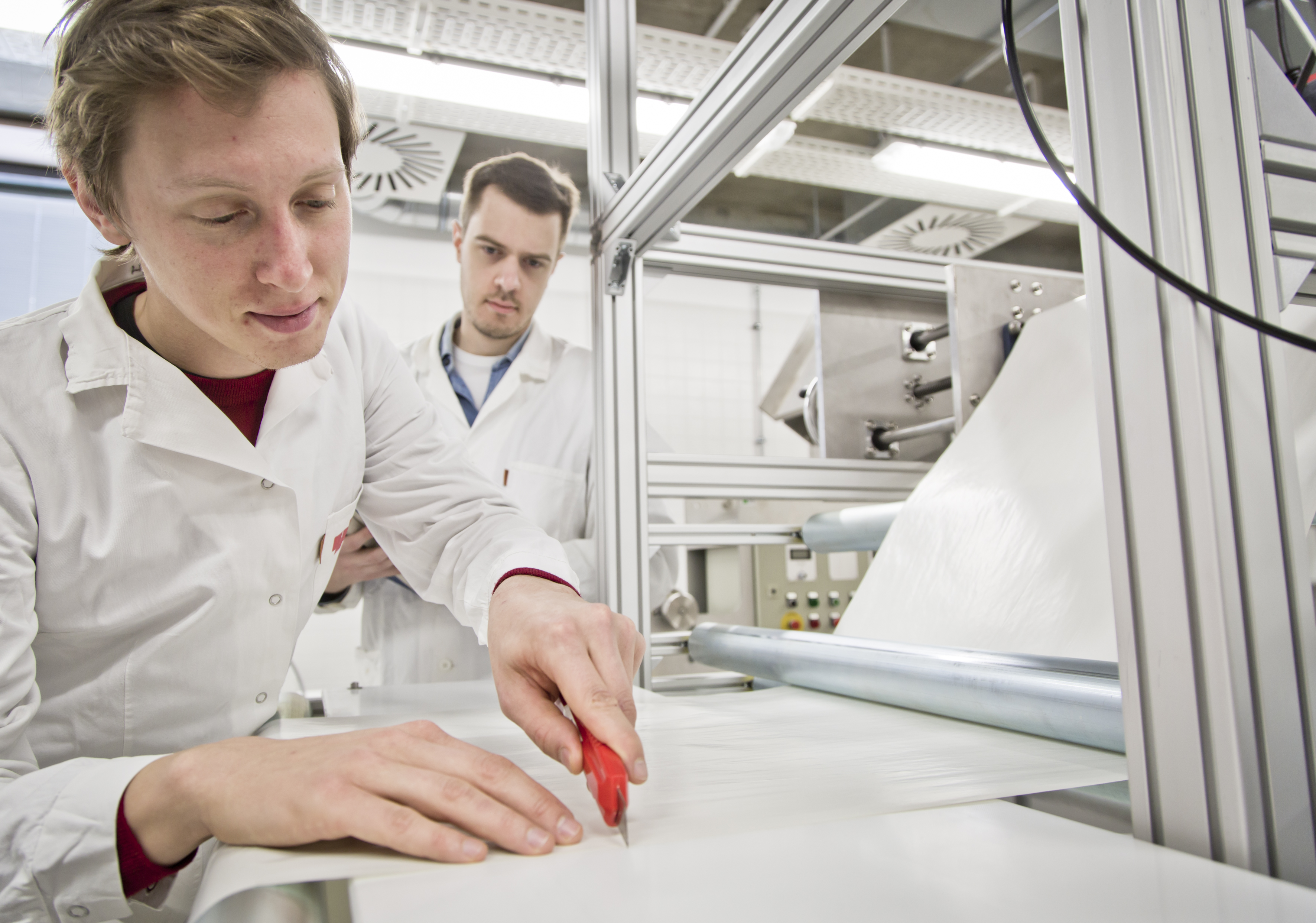

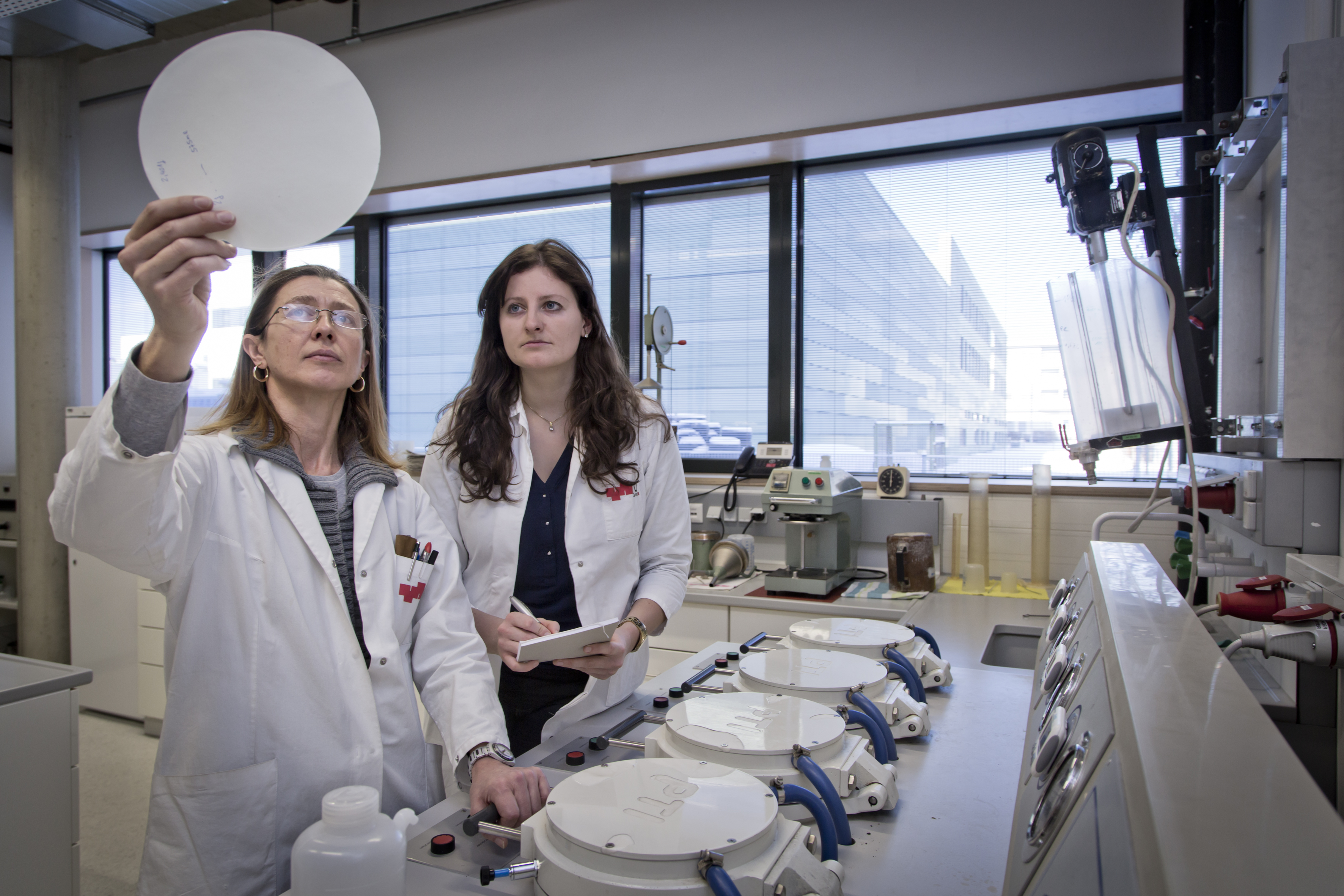

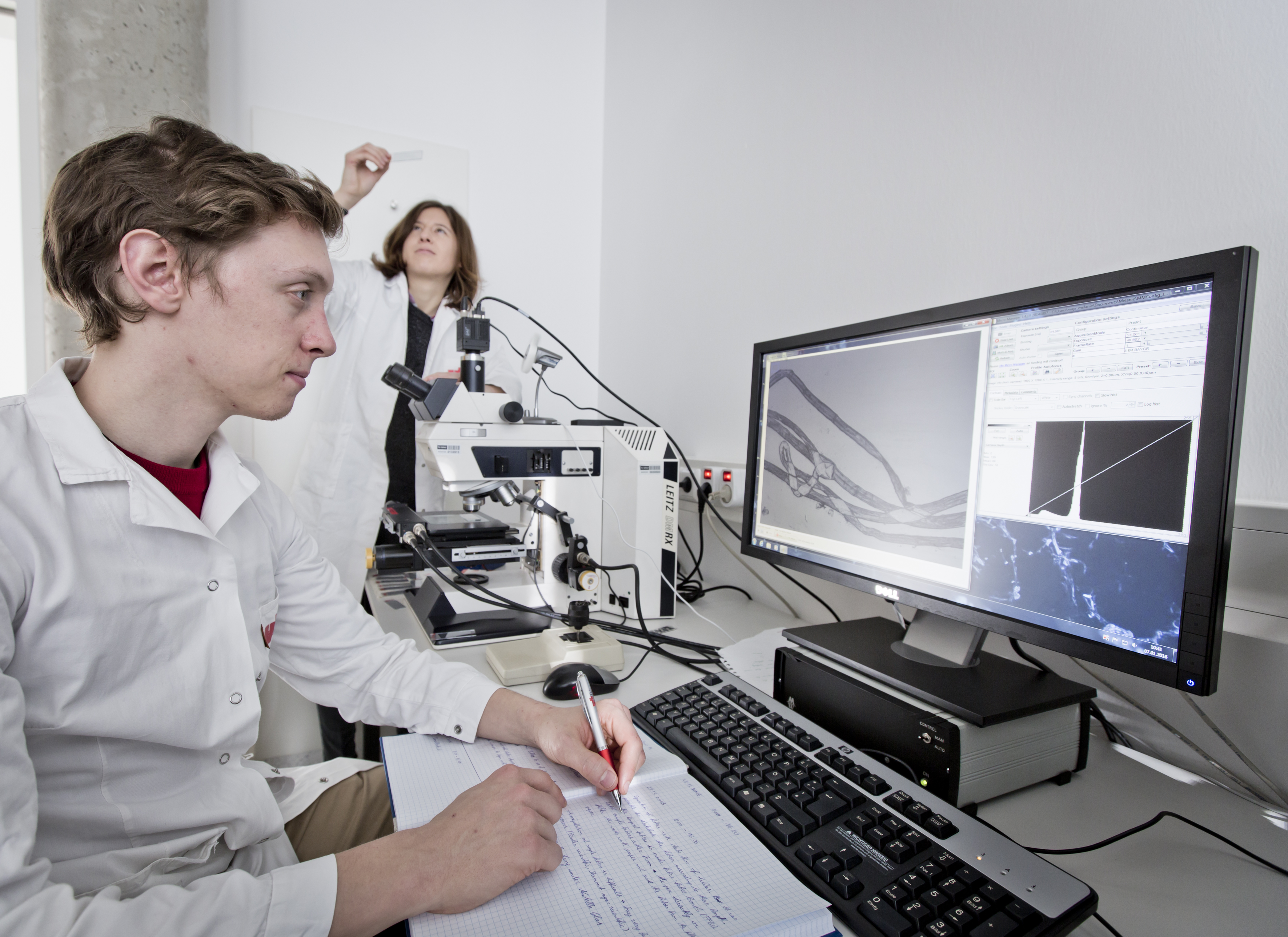

Paper is produced from renewable natural resources and – contrary to many other packaging materials – it is biologically degradable. As an everyday product, it seems to hold few secrets. In spite of this, many questions remain unanswered. For instance, it is still unclear how individual paper fibres behave if printer’s ink is applied, or how moist paper can be prevented from bulging or curling up. The team of Ulrich Hirn from the Institute for Paper, Pulp and Fibre Technology at Graz University of Technology is searching for scientifically sound explanations in the recently opened CD laboratory. As Ulrich Hirn, Head of the Laboratory, points out, “The swelling processes within the paper fibres are particularly relevant in modern high-speed inkjet printers. The less swelling occurs, the quicker the paper will dry. On the other hand, swollen fibres increase the strength of paper. If we are to optimally mix paper properties for each field of application, we need to understand, describe and ideally simulate the absorption of water as well as the mechanical processes down to the individual paper fibre. In the next seven years, this is our mission in the CD laboratory.”

More specifically, the team of the CD laboratory plans to establish precise mechanical models of the swelling processes that occur when paper is wetted or dried, and it will develop modification and improvement concepts as the basis for paper simulation for the development of printing machines. The scientists rely on the support of two big corporate partners: Mondi Uncoated Fine and Kraft Papers, a paper company headquartered in Vienna, and Océ Technologies B.V., a manufacturer of industrial printing machines and member of the Canon group of companies with principal place of business in the Netherlands.

Christian Doppler laboratories engage in application-oriented high-level fundamental research. In this context, distinguished scientists co-operate with innovative enterprises. Christian Doppler Research Association is internationally recognised as a best-practice example for the promotion of this co-operation. Christian Doppler Laboratories are jointly financed by the public sector and the participating private companies. The most important public sponsoring agency is the Federal Ministry of Science, Research and Economy of Austria.

Kontakt

Ulrich HIRN

Ass. Prof. Dipl.-Ing. Dr.techn.

Deputy Head of the Institute of Paper, Pulp and Fibre Technology

Inffeldgasse 23 A

8010 Graz

Tel.: +43 316 873 30753

ulrich.hirn@tugraz.at

www.ipz.tugraz.at