Searching for traces: Recovering gold, copper and aluminium from waste.

Via optimisation to precision

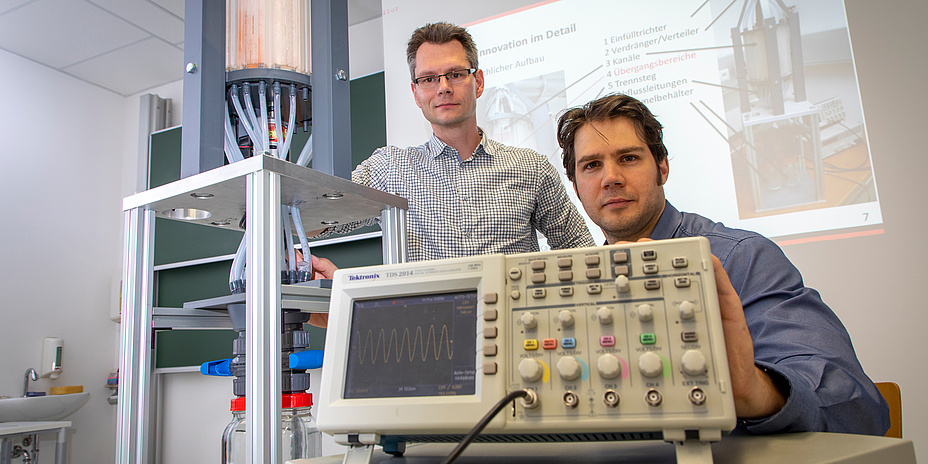

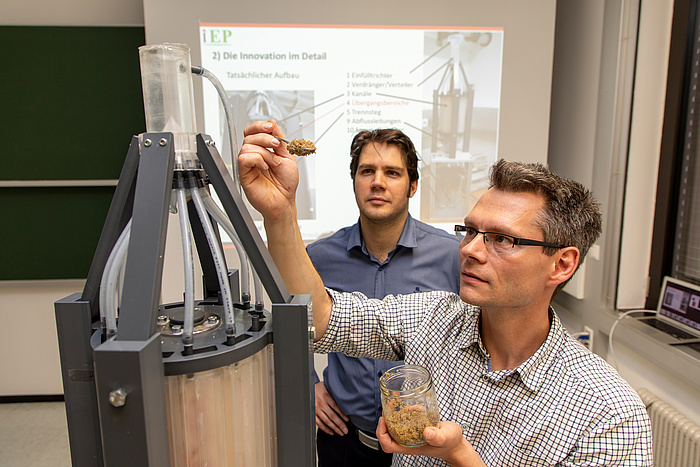

The industriy-oriented prototype which has meanwhile been developed by Hauser and Koch is the size of a fridge and is based on the principle of eddy currents. Strong magnets each with a 1 cm edge length are attached to rotating discs inside a cylinder. Their rotary motion results in a rotating magnetic field on the cylinder surface which produces an eddy current in non-ferrous metals which are trickling past. ‘We are aiming at particle sizes of about 1 mm or even less,’ explains Hauser; ‘Particles of such small size, however, react very weakly to a magnetic field. For this reason, the holding time of the particle in the reach of the field is very important.’ To raise this holding time, separation can also take place under water, the viscosity of which ensures that even the smallest particles are separated. To process river-borne gold, the material channels fastened to the outside of the cylinder are filled with water. A repulsion effect – conductive particles become themselves small magnets with reversed polarity for a short time – guide the non-ferrous particles along a different trajectory, and this enables separation from non-metals to be done. ‘Imagine it like this: when the conductive particle enters into the rotating magnetic field, it will be carried away by it,’ says Hauser, explaining the principle behind it. When separating aluminium, a pure separation from other particles is already possible.The project of Andreas Hauser and Markus Koch was funded by PRIZE through Austria Wirtschaftsservice (aws) and was supported in terms of patent law and researches regarding exploitability and patentability. The Institute of Experimental Physics, headed by Wolfgang Ernst, participated in the project by granting materials and production services.

Opportunity knocks for waste management

At this year’s Phoenix prize awards ceremony, Hauser and Koch won second place with their submission ‘System for the recovery of non-ferrous metals from incineration residues in thermal waste recycling’.

The (gold) search continues

The possible fields of application for Hauser and Koch’s development are manifold and go beyond waste management since increasingly scarce raw materials are making the use of highly developed technologies necessary, for instance in mining. In waste management there is keen interest in the prototype developed at Graz, which was shown by this year’s Phoenix awards ceremony, where Hauser and Koch won second place. ‘Our aim was to produce a device that is built in an industrially oriented way and which can be taken up by an industrial research department in the field of waste recycling,’ says Andreas Hauser, detailing the original plans. Koch and Hauser are currently looking for international partners to license their invention.This research project is attributed to the Fields of Expertise "<link https: www.tugraz.at en research fields-of-expertise advanced-materials-science overview-advanced-materials-science _blank int-link-external external link in new>Advanced Materials Science" and "<link https: www.tugraz.at en research forschungsschwerpunkte-5-fields-of-expertise mobility-production overview-mobility-production _blank int-link-external external link in new>Mobility & Production“ two of TU Graz' five strategic areas of research.

Visit <link https: www.tugraz.at en tu-graz services news-stories planet-research all-articles _blank int-link-external external link in new>Planet research for more research related news.

Kontakt

Ass.Prof. Mag.phil. Dipl.-Ing. Dr.phil. Dr.techn.

<link https: www.tugraz.at en institutes iep home _blank int-link-external external link in new>Institute of Experimental Physics

Tel.: +43 316 873 8157

<link int-link-mail window for sending>andreas.hauser@tugraz.at Markus KOCH

Assoc.Prof. Dipl.-Ing. Dr.techn.

<link https: www.tugraz.at en institutes iep home _blank int-link-external external link in new>Institute of Experimental Physics

Tel.: +43 316 873 8161

<link int-link-mail window for sending>markus.koch@tugraz.at