Award-Winning Research: Microbiomes, Hydrogen and Exoskeletons

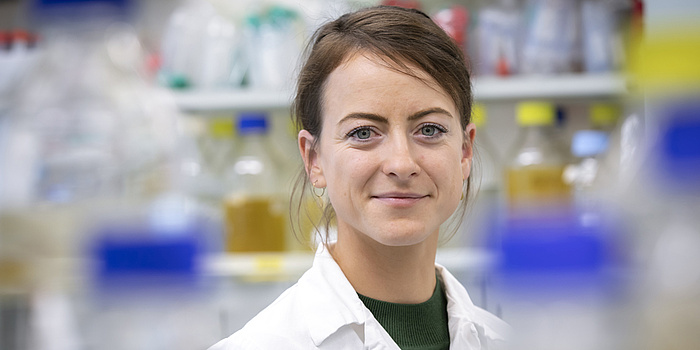

Birgit Wassermann

Millions of microorganisms made it easy for Birgit Wassermann to choose her future field of research: "Microbiome research is a relatively young field of research, so basic research is just as much in demand here as industry-relevant research, which makes this field particularly interesting for me."

that got her excited about microbiomes: "Both the impressive potential of microbiome research for our health and that of our environment, and Gabiele Berg herself, who is definitely a great role model for women in technology, made the decision to do a PhD easy for me."

During her PhD, she was able to work on a very natural topic, studying the seed microbiome of alpine plants. "Studies on natural habitats can provide us with important information about fundamental interactions between plants and microorganisms, and thus help us, for example, to develop alternatives to chemical plant protection." In her work, she was able to show which microorganisms are passed on from the mother plant to the plant offspring via the seed in an intact environment.

At the same time, she took on a junior research project that looked at the apple microbiome. "Together with pupils from three Graz school classes, we identified and quantified the microorganisms in the skin, core and flesh of the fruit." A research work that caused a broad, international echo. "None of us would have expected that," the researcher still marvels today.

For further information on the Apple Microbiome project please visit the project-website.

Today Birgit Wassermann holds a post-doctoral position at the international acib competence centre and the Institute of Environmental Biotechnology. She has decorated her office at Campus Neue Technik with countless green-leaved plants and tells us that indoor plants not only have a positive effect on the indoor climate, but that the microbiome of these plants also interacts with us and our microbiome, which has a positive effect on health.

"I love my work. It is interesting and varied and has great potential to solve the problems of the present and the future."

Birgit Wassermann investigates the microbiome of several plants. © Langhammer – TU Graz

Sebastian Bock

Sebastian Bock is carrying out research on a niche technology with future potential. He is dealing with the decentralized production of high-purity hydrogen from biomass or biogas, such as waste wood or agricultural waste. Traditionally, hydrogen is produced from natural gas. “In Austria in particular, however, we have very high potential for biomass and biogas. We should and want to make efficient and economic use of this,” explains Bock. To this end, as part of a team at the Institute of Chemical Engineering and Environmental Technology, he has adapted a chemical looping process. This method makes use of the capabilities of metals as oxygen carriers in oxidation and reduction reactions. “Currently, the process is mainly proposed for new, CO2-neutral power plants in the energy industry – unfortunately mostly from fossil fuels.” The process is mainly used to capture pure carbon dioxide. The keyword here is carbon capture and storage.

Sebastian Bock and his team are now using the process to produce high-purity hydrogen. First, the iron oxide is reduced using biogas or biomass and then oxidized using steam. This produces 99.999 per cent high-purity hydrogen. “Especially in mobility and parts of industry, high purity is extremely important,” he explains. “We want to make it possible for hydrogen to be produced in a decentralized way for local use and not, as is currently the case, having to be stored at great expense and transported at great cost.” The 31-year-old’s task in the project was to prove the process, hydrogen purity and high efficiency at the laboratory scale. Which he managed to do. “The system was implemented together with a biogas plant operator in Mureck as a small demonstration system. It’s more symbolic at the moment, but for example tractors could be run on hydrogen from the plant.”

Sebastian Bock demonstrated a system for the decentralized production of high-purity hydrogen at the Institute of Chemical Engineering and Environmental Technology. © Lammer, TU Graz

Matthias Wolf

Matthias Wolf came to his research topic, exoskeletons, in a very personal way. “I used to play handball and hurt my shoulder several times. I tried a lot of aids like bandages and wished there was something that really helped.” Today, Wolf, of the Institute of Innovation and Industria Management, is concerned with how companies can design workplaces in such a way that they function efficiently and conserve resources, but above all do not have any negative effects on the physical, mental and social well-being of their employees. “This is as relevant for the people working as it is for the company itself and the economy.” After all, sick leave costs money. And in many cases, not just a bit. In his Master’s thesis, Wolf dealt with standards and regulations for workplace design. The now 34-year-old examined whether they are suitably adapted to the changing demographic conditions. “In addition to the shortage of skilled workers, which we are already noticing today, working people are also getting older on average. The working environment must also comply with this development.”

Building on the results of these studies, Wolf dealt with age-appropriate workplace design in his doctorate. Here, primarily with technologies that support healthy working. “I’ve mainly been looking at production work and how exoskeletons, for example, can be used efficiently with industrial partners.” Exoskeletons are divided into active and passive devices. Active exoskeletons provide support via actuators and can theoretically increase the performance (e.g. strength) of employees. Passive exoskeletons are mechanical systems, such as spring-damper systems that tighten when bending forward and then return the force when lifting and straightening up, reducing the load on the back. In large production plants, such as the automotive industry, these mechanical devices are already being tested and used. But in smaller companies, studies on applicability and support effect are still largely lacking. “We are looking at that at the moment, under the premise of whether the use of exoskeletons makes sense for small and medium-sized enterprises and to what extent the high acquisition costs are justified.” Questions that Wolf now also wants to answer in his habilitation.

Matthias Wolf is investigating how working conditions can be optimized so that they do not harm people either physically or psychologically. © Baustädter – TU Graz

You can find more research news on Planet research. Monthly updates from the world of science at Graz University of Technology are available via the research newsletter TU Graz research monthly.