Professorship “Aviation Materials and Manufacturing Techniques”

In 2019, commercial flights worldwide produced approximately 915 million tons of CO2. In response to this critical situation, the European Commission (EC) has recently set a target to achieve climate neutrality by 2050. One way to achieve this goal is to develop greener (e.g. hybrid electric aircraft, fuel cells powering electric motors) propulsion systems in lighter and more sustainable aircraft.

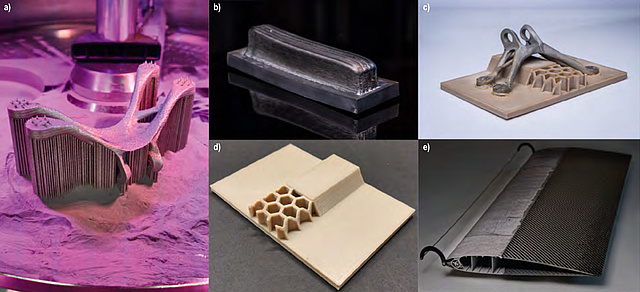

The team, led by Sergio Amancio, aims to develop innovative and novel engineering approaches to produce lightweight and high performance light metals, composites, and metal-composite hybrid structures. The team focuses on sustainable materials with improved recyclability to support the circular economy. Examples include carbon and glass fiber reinforced thermoplastic composites - a class of recyclable and repairable composites - that can be combined with lightweight and high strength alloys, such as aluminum and titanium and stainless steel, to reduce aircraft weight without compromising passenger safety. More recently, wood-thermoplastic composite and wood-metal hybrid structures have been investigated with a focus on secondary and tertiary structural applications (e.g. interior, cabin and cargo applications).

Society of Plastics Engineers, SPE

(SIG-12 - Joining of Polymer and Composites); USA

International Institute of Welding, IIW

(Commission III “Resistance Welding, Solid State Welding and Allied Joining Processes”, and Commission XVI “Polymer Joining and Adhesive”)

Deutsche Gesellschaft für Materialkunde e.V., DGM

(German Materials Society) Technical Committee „Hybrid Materials and Structures“