Thermal Energy Systems and Biomass Utilisation

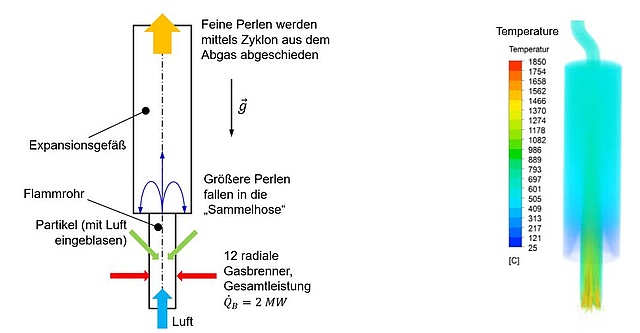

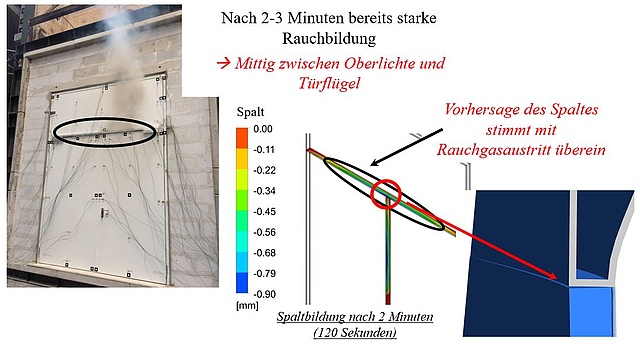

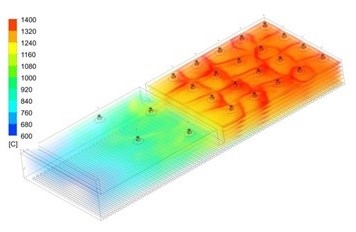

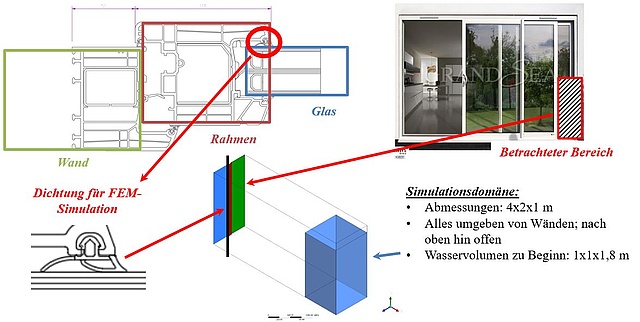

In cooperative research projects, combustion simulations of melting and annealing furnaces are carried out and the heat management of different systems is investigated by using numerical methods. The numerical simulations are performed using Computational Fluid Dynamics (CFD), Finite Element Methods (FEM) and Lattice-Boltzmann Methods (LBM).

In joint research projects, combustion simulations of melting and annealing furnaces are carried out and the thermal management of different systems is investigated using numerical simulation methods. The numerical simulations are carried out using Computational Fluid Dynamics (CFD), Finite Element Methods (FEM) and Lattice-Boltzmann Methods (LBM).

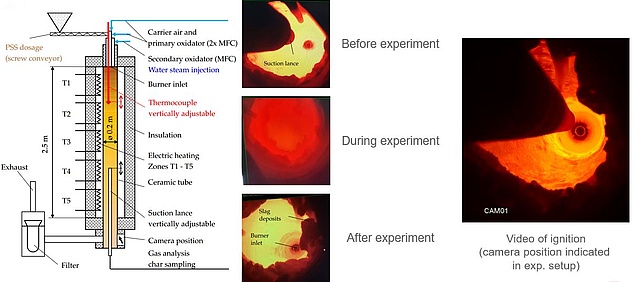

- Experimental investigation of combustion of low-calorific fuels with pure oxygen

- Experimental development of a heat recovery system for oxy-fuel plants by means of internal reforming of the fuel

- CFD simulations of steam sterilization processes

- Numerical investigation of next generation steam sterilizers

- CFD investigations of the sterilization process of medical devices

- Development of the reliability- and durability diagnosis tools for solid oxide fuel and electrolysis cells

- Degradation monitoring and performance optimization of high temperature electrolysers

- Reversible solid oxide cells for electrochemical energy conversion and energy storage

- Experimental characterization and evaluation of special fuels (such as: ammonia, wood synthesis gas, biogas, diesel, ethanol, ...) for application in solid oxide fuel cells

- Electrochemical characterization and performance assessment of SOC stacks in reversible operation

- Industrial hydrogen combustion systems

- Decarbonisation of combustion systems through hydrogen enrichment

- Reduction of oxidation rates of metallic components in heat treatment furnaces

- Determination of scale formation of metallic components in heat treatment furnaces for different fuels such as hydrogen, natural gas, ammonia, substitute fuels

Infrastructure

General test rigs:

- Mechanical & electrical workshop

- Chemical laboratory

- Fuel cell laboratory

- Reforming test rig

- Burning chamber with chimney (up to 1,2 MW)

- Central heat sink (water re-cooling system up to 5 MW)

- Several (mobile ) heat sink & heat source systems

- Climatic chamber (-20 to +40°C)

- Vehicle air-conditioning test bench

- Absorption heat pump system

- Furnace for all relevant liquid fuels (heating oil EL and S, slurries, sewage sludge)

- Furnaces for all relevant gaseous fuels (e.g. hydrogen, natural gas) and all relevant oxidifiers (e.g. pure oxygen, air) suitable for combustion tests, heat treatment of components (up to approx. 1300°C), burner development and investigation of fuel mixtures (esp. Hydrogen-natural gas mixtures)

Measurement Technology

Measurement equipment:

- All typical sensors required for flow rate, pressure, humidity, temperature, etc.

- Gas analyzer (GA)

- Gas chromatograph (GC)

- Fourier transform infrared spectroscopy (FT-IR)

Division

Thermal Energy Systems and Biomass

Univ.-Prof. Dipl.-Ing. Dr.techn.

Christoph Hochenauer