AuReLiA - Automated assessment strategy for recyclates in food contact - interdisciplinary approaches

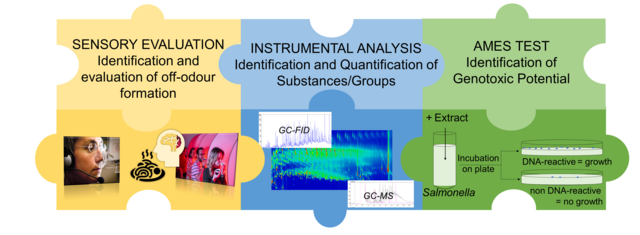

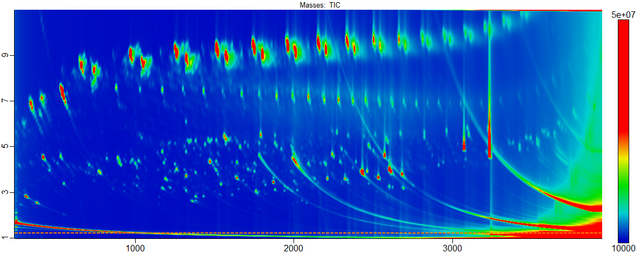

Europe’s vision of a new circular economy regarding packaging materials aims to make all plastic packaging produced in the EU market reusable or recycled in a cost-effective manner by 2030. Subsequently, the development and deployment of highly efficient sorting procedures and recycling processes are needed to enable production of high-quality recycled products, as well as analytical strategies for their characterization and safety evaluation. The regulatory details were only lately published by the European Commission in its new regulation (EU) No. 2022/1616 on recycled plastic materials for food contact. It allows newly developed, non-authorized technologies and approaches, so-called ‘novel technologies’, to be deployed in the field and bring products to the market. One of the key points is to guarantee processes and materials that are safe to use for the consumer. This should be reached by comprehensive characterisation of the materials and processes. However, the regulation does not give a more detailed description on suitable methods and parameters for testing and monitoring of those. The main aim of this project is to develop an assessment strategy that generates the needed data for the approval of novel technologies and to guarantee consumer safety of the generated products for food contact according to regulation (EU) No. 2022/1616. Thereby, also the principles of Regulation (EG) No. 1935/2004 that food contact materials should not change the food in any unacceptable way, neither in terms of taste or quality nor contaminations, are indisputable. To make the generation of needed data as easy as possible, the automation of the developed analysis approach is a key goal of the project. In a first step, data and knowledge on processes and materials shall be generated by using an interdisciplinary approach.