To achieve the described objectives, research tasks concerning the following main topics have to be conducted:

- Joining technology:

Powerful adhesive systems contribute significantly to the overall costs. Thus, alternative, cost-efficient and powerful ways of connecting wood and metal are investigated. - Adhesive-free joining techniques (form fit, frictional connection, integrated connections using beading, ribs etc.)

- Mechanical fasteners made of polymeric materials (friction welding dowels and rivets)

- Investigation of the alternative connection technologies regarding technical properties, costs and possibilities of serial production

- Wood modification:

Wood has no unlimited resistance to biotic and abiotic stresses. Through wood modification, these properties can be changed. However, wood modifications also increase costs. Therefore, in Bio!LIB, such modifications shall only be used locally (e.g. in the outer layers): - to impede metal corrosion at the interface between metal and wood (thermally modified wood),

- to increase the durability by using modified veneers (acetylation, furfurylation, high pressure laminates),

- to further reduce the thermal conductivity coefficient (delignification),

- and to increase the flame retardant effect (sodium silicate, salts).

- The technical properties, costs and possibilities of serial production of modified wood-laminates are investigated.

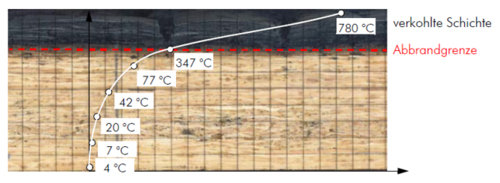

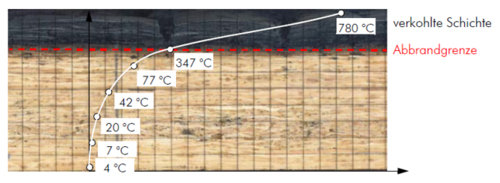

- Fire performance in battery housings:

- Reaction of gases, which are produced during wood charring, with the leaking gases and liquids of a burning Li-Ion-cell

- Outgassing behavior, burn rate and thermal conduction coefficient - with and without oxygen restriction ("Tightness" of the battery housing)

- Ecological footprint:

Steel and wood belong to the more ecological materials. However, both the production and the EoL-phase still offer room for improvement. Approaches to reduce the necessary amount of energy during production (drying plants, hot pressing, ..) and to maintain the seperability of materials are explored.