In-line determination of thermo-physical and electromagnetic properties from system data of induction heating facilities (SysDatMat)

This project focuses on developing innovative methods to identify and extract thermo-physical and electromagnetic properties of materials during induction heating processes. We employ two main strategies:

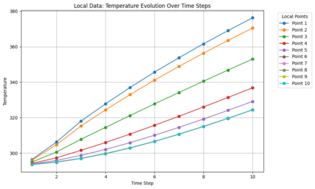

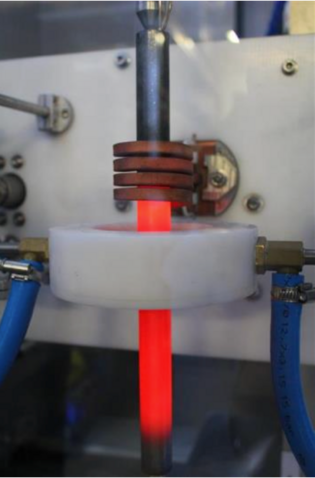

- Real-Time, In-Line Data Analysis: By collecting and evaluating data directly from industrial induction heating facilities, such as those used for preheating forgings, steel strip heating in continuous annealing/galvanizing lines, and induction hardening, we enable immediate insights into material behavior.

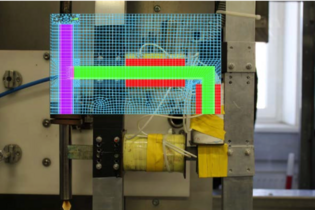

- Modular Sensor & Software System: We are also creating an independent sensor and software solution that can be seamlessly integrated into production systems. This includes not only induction heating setups but other manufacturing processes as well.

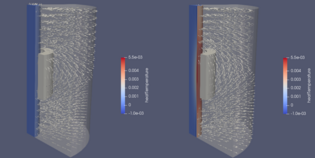

To achieve these goals, we leverage Physics-Informed Neural Networks (PINNs) and Finite Element (FE) simulations, capturing both electromagnetic and thermo-physical parameters with high accuracy. Advanced FEM methods for multiphysical magnetic-thermal simulations incorporating temperature-dependent magnetization curves and solution-dependent thermal properties, lie at the heart of our approach. These specialized numerical techniques help ensure reliable performance and efficiency, ultimately empowering manufacturers with deeper, data-driven insights and enhanced control over their processes.