High-quality manufacturing of pre-material for automotive components (HQ-AutoMat)

Our project aims to support high-quality production of galvanized 3rd generation AHSS (Advanced High-Strength Steel) strips and Q&T (Quenched and Tempered) rod materials for automotive applications. This initiative aligns with Green Deal objectives and the Twin Transition vision by incorporating innovative strategies and digitalization methods.

Key project goals include:

- Developing a numerical tool to assess the homogeneity of austenitization, including both temperature and austenite formation under inductive heating, while also gaining first insights into zinc layer formation on inductively treated strips.

- Establishing a guideline for a new coating on zinc bath sink rolls that delivers high wear resistance, withstands zinc corrosion, and minimizes dross buildup.

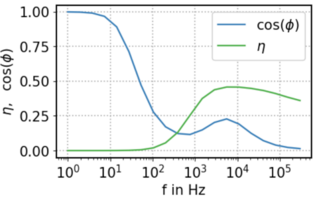

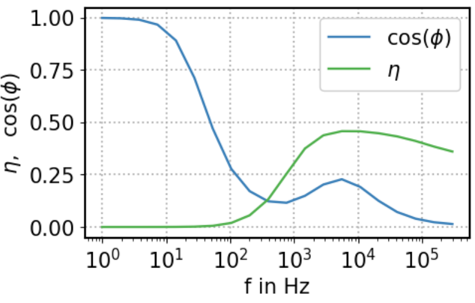

- Creating physics-based correlations between microstructural features and magnetic properties, laying the groundwork for future in-line quality management and process control methods.

At TU Graz, our primary contribution to this interdisciplinary effort involves:

- Macroscopic Magnetic Material Models and Measurements on Cylindrical Rod Materials: We develop realistic, physics-based magnetic (and magnetomechanical) models, then benchmark these against micromagnetic simulation results. Macroscopic models are especially valuable for large-scale Finite Element (FE) simulations, while micromagnetic simulations provide detailed, microscopic-level reference data.

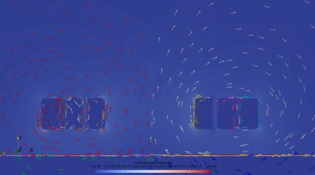

- Advanced Finite Element Simulation & Optimization Tools: Using our open source simulation software (openCFS), we perform coupled multiphysical magneto-thermal induction heating simulations. These specialized tools enable us to address the complexities of temperature-dependent, large-scale industrial processes.

By bridging the gap between microscopic simulations and full-scale engineering applications, our work supports manufacturers in optimizing production, enhancing material performance, and ultimately contributing to more sustainable and efficient automotive solutions.

Magnetomechanical material model development