Material Characterisation and Inverse Methods

The quality of the numerical simulation depends largely on the material models used and their parameters. As the material parameters often cannot be measured directly, global physical quantities (e.g. electrical impedance) are determined and attempts are made to identify the material parameters using inverse methods by modifying them using an inverse scheme so that the globally measured quantities match the simulation. This usually leads to poorly defined problems that require special mathematical treatment. Deterministic, stochastic and hybrid strategies are used to solve this special class of optimisation problems.

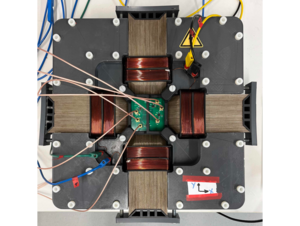

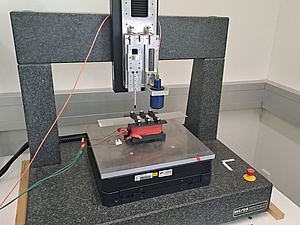

The materials laboratory at the IGTE comprises (1) Epstein frames for characterising purely uniaxial magnetic properties in the temperature range from -20°C to 180°C; (2) Rotational Single Sheet Tester (RSST) for determining the magnetic material properties of anisotropic electrical sheets, in particular the rotational losses; (3) Helmholtz coils for characterising solid bar materials and for calibrating magnetic sensors; (4) Pulse magnetiser and hysteresis graph for hard magnets; (5) Magnetic coordinate measuring machine for 3D scanning of hard magnets and for assessing the homogeneity of a magnetic field as well as for investigating the influence of different cutting processes on electrical steel sheets; (6) Impedance and transmission tube for measuring acoustic material properties; (7) 3D laser scanning vibrometer for vibration measurements.