Design of electro sheet processing for improved efficiency of e-mobile drives (DESID)

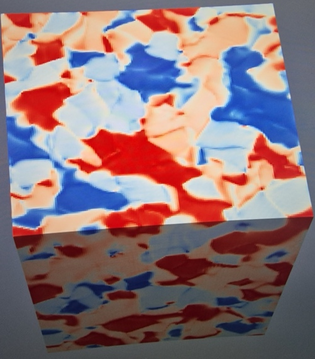

This project aims to design electrical steel sheets that deliver enhanced efficiency in e-mobility drives. By leveraging custom-tailored processing techniques, we can optimize the microstructure of the sheet material and mitigate the negative impact of punching on electromagnetic losses near sheet edges.

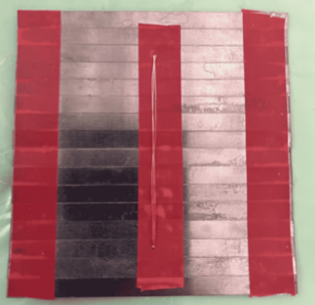

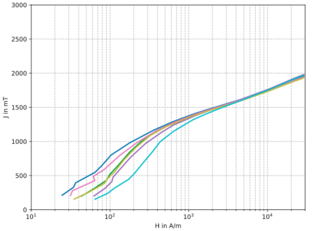

This highly interdisciplinary initiative involves multiple partners from both industry and academia. At TU Graz, our primary role is to evaluate, measure, and interpret how various factors such as punching wear and different heat treatments affect the magnetic properties of the sheets. To achieve this, we utilize our Rotational Single Sheet Tester (RSST), conducting measurements at very low frequencies (<0.5 Hz) and higher frequencies (around 200 Hz).

By identifying and understanding the key correlations between cutting parameters, heat treatment, and magnetic behavior, we aim to assist manufacturers to fine-tune their processes. The ultimate goal is to develop electrical steel sheets that not only exhibit optimal magnetic performance but also significantly contribute to improved efficiency and reliability in next-generation e-mobility systems.